阿里News

News

- 阿里Common sense of daily maintenance of rotomolding tray

- 阿里SARS CoV's attack, Shengyun to be the leader of the enterprise

- 阿里What are the characteristics of roll forming technology of 30 cm roll forming floating ball

- 阿里Common quality problems of rolling process in molding of rolling products

Contact Us

WeChat : +86 13482230296

WhatsApp: +86 13482230296

Online:+86-139-1884-6842

Email:bin.su@syroto.com

Address: 2555 xiupu Road, Kangqiao Town, Pudong District, Shanghai ,China

Industry News

阿里Analysis of common problems in roll forming

- Author:

- Time: 2020-05-21 21:03:10

- Click:20196

Today, I'd like to share with you the quality problems of roll molding products

There are many factors that affect the quality of roll molding products, among which the shape of the mold, the rotation speed of the mold, the heating temperature and time of the mold, the physical characteristics of the plastic powder and so on are more important.

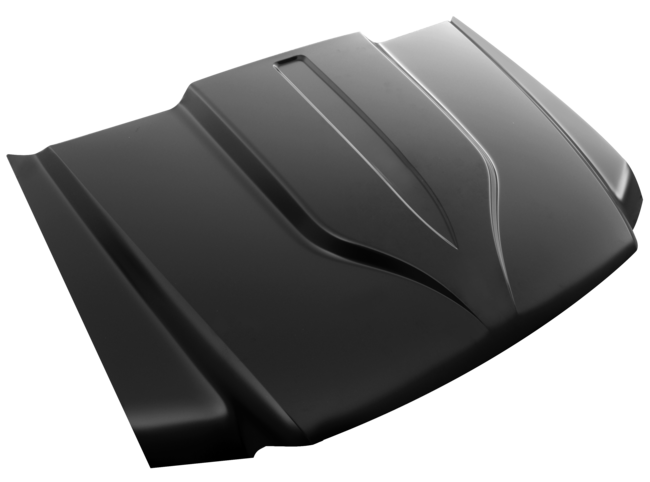

Roll plastic leakproof tray

1. The mold for rotational molding is a single wall closed mold. It gives the outline of the product, but it can't get the details of the internal outline of the product. Generally, the material of the mould for spinning plastic is common carbon steel plate welding. The cost of welding die is relatively low, especially suitable for large-scale rotational plastic products. The basic requirements of spinning process for its mold are as follows: the mold is not easy to deform and flex in the process of repeated heating and cooling. The mould shall be attached with a clamping mechanism which is easy to loosen, so that the mould can be closed tightly in the heating and cooling process, and can be easily opened when the products need to be unloaded and loaded. The design and installation of the die should be conducive to the relative movement of air flow around the die surface, so that the die can be evenly heated and cooled. The mould shall be provided with vent pipe to prevent the molten plastic from extruding along the joint due to the expansion of gas in the mould during the heating process, and to prevent the mould and products from deforming due to the negative pressure generated in the mould during the cooling process. Deep cavities and holes, as well as stiffeners and solid protrusions, should be avoided in the design of the local structure of the mold, because it is difficult for the powder like materials to cover the surface of the above structure. The sum of die weight and material weight shall not exceed the maximum bearing capacity of the spinning machine.

2. Generally, two adjustable motors are used in the rotational speed of the rotational molding machine to provide power for the rotation and swing of the mold around the main shaft and the secondary shaft, so that the rotational speed of the mold around the main shaft and the swing around the secondary shaft can be adjusted. By adjusting the rotation speed of two speed regulating motors, the operator can obtain relatively uniform product wall thickness under any product shape. The basic function of die rotation and swing is to make the powder materials mix evenly and spread all over the die surface.

Rolling plastic insulation box

3. The particle size of polyethylene powder the particle size of polyethylene powder has an important influence on its melting process. The smaller the particles, the larger the ratio of surface area to volume, the higher the melting rate. Generally, the size of powder particles should not be less than 30 mesh. However, the size of powder particles should not be too small, because too fine powder is easy to absorb moisture and agglomerate, so it is difficult to dry, which increases the difficulty of technology. Too fine powder material will agglomerate when rolling in the mold, resulting in uneven heating of the powder, resulting in uneven product wall thickness or incomplete melting of plastic in the product. The experiment shows that the particle size of polyethylene powder added into the spinning mould once is not uniform or even, and the orderly particle size is in the heating mould. Because of the length and speed of the endothermic melting time of the coarse and fine powder, the melting plastics gradually pile up and gradually form. The fine powder mixed in the coarse particles can reduce the friction of the coarse particles, which is conducive to the rolling and flow of the materials in the mold. At the same time, the existence of fine powder is also conducive to the refinement of the product surface, reducing the porosity of the product section, and improving the product quality.

4. If the heating time and cooling time are too short, the powder will not melt completely, and the plastic performance will not reach the best index. If the heating time is too long, the plastic will be oxidized, which will damage the molecular structure of the plastic. It is easy to aging and brittle, which will affect the quality of the rolled plastic products. The cooling time is also very important. If the cooling time is too fast, it will easily deform the products, and affect the usability and aesthetics of the products.

Rolling plastic sewage lifter

The above are several common factors that affect the roll molding products, and other factors will be discussed slowly with you later.

中文网站

中文网站