News

News

- Common sense of daily maintenance of rotomolding tray

- SARS CoV's attack, Shengyun to be the leader of the enterprise

- What are the characteristics of roll forming technology of 30 cm roll forming floating ball

- Common quality problems of rolling process in molding of rolling products

Contact Us

WeChat : +86 13482230296

WhatsApp: +86 13482230296

Online:+86-139-1884-6842

Email:bin.su@syroto.com

Address: 2555 xiupu Road, Kangqiao Town, Pudong District, Shanghai ,China

Industry News

Common quality problems of rolling process in molding of rolling products

- Author:

- Time: 2020-05-21 21:08:54

- Click:26222

The quality of rolling products is undoubtedly the most concerned problem of manufacturers and users. The quality of rolling products is closely related to product design, mold, raw materials and process conditions.

Next, we will introduce some quality problems of rolling products to you, analyze the causes and give the corresponding solutions.

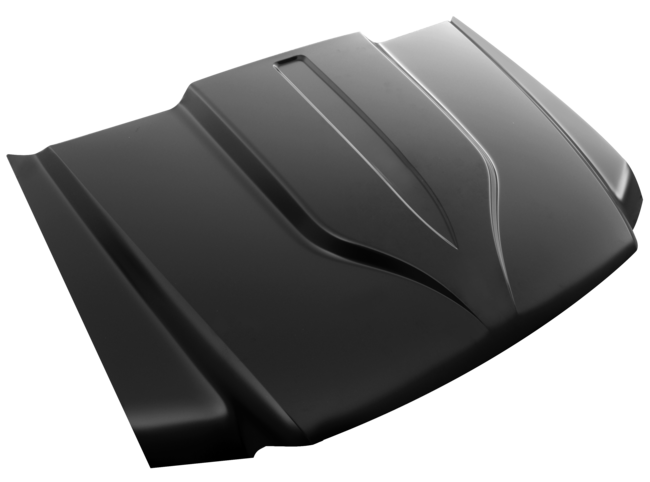

Rotational molding

1. Bubbles and holes on the product wall

The causes of the surface holes and internal bubbles are as follows.

1.1: raw material powder or inner wall of mould is wet, which promotes bubble increase.

1.2: the viscosity of resin melt is large, and the bubbles are not easy to be discharged.

1.3: the resin is not fully heated, and there is not enough power and time to remove bubbles.

1.4: the vent pipe is blocked and the internal gas cannot escape.

2. Rough inner wall of products

2.1: the resin is not sufficiently heated, melted and leveled.

2.2: the viscosity of resin melt is large and the flow is difficult.

2.3: the raw material particles are coarse or irregular in shape, especially with long filamentous and curly particles.

3. Discoloration of the inner wall of the product

The main reason for the yellowish brown of the inner wall of the product is the oxidation and degradation of the resin caused by too high heating temperature or too long heating time.

Rolling straw cart

4. The product is narrow and the depression is not full

4.1: improper design of products and moulds

4.2: the resin is not fully heated and melted

4.3: the viscosity of resin melt is large and its fluidity is poor

4.4: the raw material particles are mixed with long filamentous and curly particles

4.5: improper mold rotation speed and speed ratio

5. The product has flash

Flash refers to the phenomenon that the semi melted resin overflows from the gap of the parting surface of the mold during the heating process. The main causes of flash are as follows.

5.1: the mold parting surface is not closed tightly

5.2: mold vent blocked

6. Uneven wall thickness of products

6.1: the wall thickness of the mold itself is uneven, or the thermal conductivity of each part is different

6.2: improper mold installation position, uneven heating of all parts

6.3: improper mold rotation speed and speed ratio

7. Product bonding mold

7.1: no release agent is used, or improper use of release agent

7.2: rough and scratched mold surface

7.3: insufficient cooling of products

7.4: Die inclination is too small

Rolled military box

8. Shrinkage and deformation of products

8.1: the cooling rate is too fast, or the cooling of each part is uneven

8.2: excessive use of release agent

8.3: mold vent blocked

8.4: improper pigments and other fillers are used

9. Poor impact resistance

9.1: poor impact resistance of raw resin itself

9.2: the resin is over heated and oxidized

9.3: slow cooling

9.4: improper variety of pigments and other fillers, or excessive amount of fillers

10. Poor product rigidity

10.1: poor rigidity of raw resin itself

10.2 small amount of raw materials and thin wall

10.3: unreasonable product design

Shanghai Shengyun rolling plastic products Co., Ltd. is a professional enterprise engaged in the processing of rolling mold and rolling plastic products. We have a first-class team of roll forming engineers in China, with more than 10 years of experience in roll forming industry, and have participated in the design and production of major roll forming projects in China, such as a project of Beijing Olympic Games, roll forming facilities of Shanghai World Expo exhibition hall, marine lampshade of Guangzhou Asian games, etc. Familiar with the design and production of floor washing machine shell, kayak, military box, engineering vehicle oil tank, water tank, food incubator and other products, the products are exported to dozens of countries in the United States, Germany, Italy, Britain, France, Japan, and the roll molding technology is at the leading level in China. It is well recognized and praised by domestic peers and customers.

Since the establishment of the company, the management, people-oriented, collaborative innovation and the pursuit of excellence have always been in an invincible position. With the concerted efforts of many employees, the performance is booming.

- Prev:What are the factors that affect the quality of rolling products

- Next:What are the characteristics of roll forming technology of 30 cm roll forming floating ball

News

-

2020-05-21

Analysis of common problems in roll forming

中文网站

中文网站