News

News

- Common sense of daily maintenance of rotomolding tray

- SARS CoV's attack, Shengyun to be the leader of the enterprise

- What are the characteristics of roll forming technology of 30 cm roll forming floating ball

- Common quality problems of rolling process in molding of rolling products

Contact Us

WeChat : +86 13482230296

WhatsApp: +86 13482230296

Online:+86-139-1884-6842

Email:bin.su@syroto.com

Address: 2555 xiupu Road, Kangqiao Town, Pudong District, Shanghai ,China

Industry News

What are the characteristics of roll forming technology of 30 cm roll forming floating ball

- Author:

- Time: 2020-05-21 21:13:08

- Click:27018

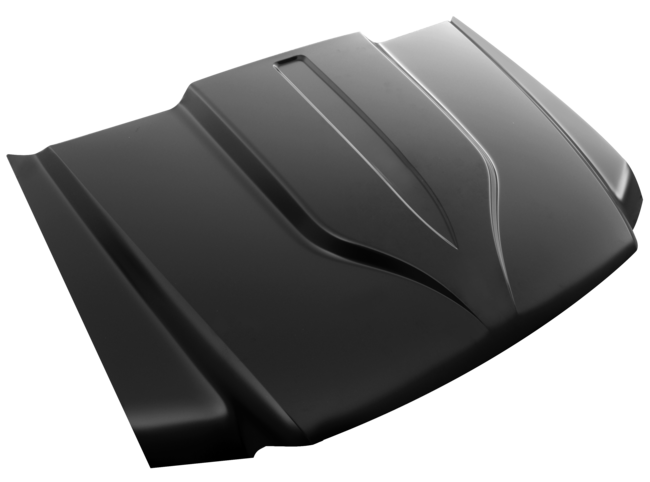

The roll forming process of 30 cm floating ball is to add the plastic raw materials into the mold first, and then the mold rotates along two vertical axes and heats them. The plastic raw materials in the mold are coated and fused on the whole surface of the mold cavity under the action of gravity and heat energy, forming the required shape, and then cooling and shaping the products The service life can be more than 20 years, and the cost performance is very high. The low cost, high quality and good solid polyurethane floating fender, also known as foam filling fender (relying on the ball), is a floating fender system which uses light high elastic foam as buffer medium and better than fender fender. It is widely used in port, offshore, underwater oil and natural gas pipelines and ship operation.

The rotomold process is characterized by:

1. Low cost of rolling mold: for products of the same size, the cost of rolling mold is about 1 / 3 to 1 / 4 of the cost of blow molding and injection mold;

2. The edge strength of the roll molded product is good, and the thickness of the edge of the product can be more than 5mm, which completely solves the problem of the thin edge of the hollow product;

3. Various inlays can be placed in the roll molding;

4. The shape of rolling products can be very complex, and the thickness is more than 5 mm;

5. Roll molding can produce totally closed products;

6. The rolling plastic products can be filled with foaming materials to achieve thermal insulation.

7. No need to adjust the mold, the wall thickness of the rolling products can be adjusted freely

8. The product is hollow and seamless, but the wall thickness can be adjusted to make the product with high strength.

9. can provide a variety of surface pattern processing, production of various color products, can be used to prevent UV aging, for a variety of stone, wood simulation results

Shanghai Shengyun roller plastic products Co., Ltd. is a professional enterprise engaged in the processing of roller mold and roller plastic products. The company is located in Wangjia Road, Qingcun Town, Fengxian District, Shanghai. It is only 30 minutes' drive from Shanghai Pudong International Airport and Shanghai Hongqiao Airport. It is close to the outer ring of Shanghai with high speed, convenient transportation and clean environment.

The company has a first-class team of roll forming engineers in China, with more than 10 years of experience in roll forming industry, and has participated in the design and production of major domestic roll forming projects, such as a project of Beijing Olympic Games, roll forming facilities of Shanghai World Expo exhibition hall, marine lampshade of Guangzhou Asian games, etc. Familiar with the design and production of floor washing machine shell, kayak, military box, engineering vehicle oil tank, water tank, food incubator and other products, the products are exported to dozens of countries in the United States, Germany, Italy, Britain, France, Japan, and the roll molding technology is at the leading level in China. It is well recognized and praised by domestic peers and customers.

News

-

2020-05-21

Analysis of common problems in roll forming

中文网站

中文网站